Automation has been a driving force in manufacturing for decades, but with the integration of artificial intelligence (AI), a new era of possibilities has emerged. In this article, Daniel Reitberg explores the synergy between AI and robotics, painting a picture of the future where machines are not just automated but intelligent collaborators in the manufacturing process.

Revolutionizing Manufacturing: The Power of AI-Enabled Robotics

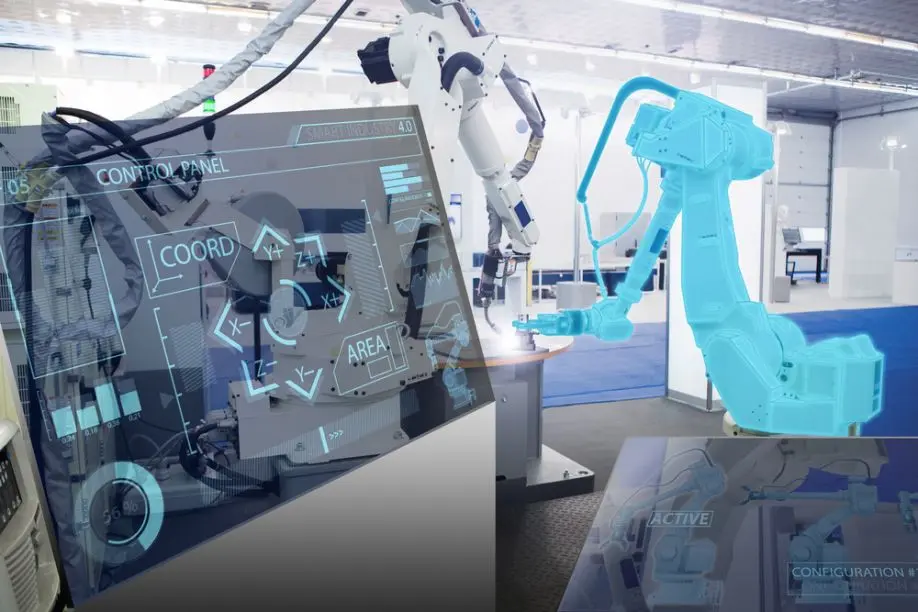

The marriage of AI and robotics marks a significant leap forward in manufacturing capabilities. Daniel Reitberg discusses how AI transforms robots from mere tools into adaptive, learning systems. These robots can analyze data, make decisions, and continuously improve their performance, making them versatile assets on the factory floor.

Enhancing Efficiency: Precision and Speed in Manufacturing

One of the most compelling advantages of AI-enabled robotics is their ability to enhance efficiency. Daniel Reitberg delves into how these robots can perform tasks with unparalleled precision and speed. They can handle intricate processes with consistency, reducing errors and production time, ultimately leading to cost savings.

Human-Robot Collaboration: A Harmonious Future

Contrary to the fear of robots replacing human workers, Daniel Reitberg highlights the concept of human-robot collaboration. AI-enabled robots can work alongside humans, handling repetitive or physically strenuous tasks, while human workers focus on more complex, creative, and decision-making aspects of manufacturing. This synergy optimizes productivity.

Continuous Learning: Robots That Adapt and Evolve

AI-empowered robots don’t stop at performing programmed tasks. Daniel Reitberg explains how they continuously learn from their experiences. By processing data from sensors and cameras, they adapt to changing conditions and become increasingly adept at their roles. This adaptability is a game-changer in dynamic manufacturing environments.

Quality Control and Predictive Maintenance: Reducing Downtime

Maintaining product quality and minimizing downtime are paramount in manufacturing. Daniel Reitberg explores how AI-enabled robots excel in quality control, spotting defects with precision. Moreover, they predict maintenance needs, reducing unplanned downtime and ensuring that manufacturing processes run smoothly.

Challenges and Workforce Implications: Adapting to Change

While AI-enabled robotics bring numerous benefits, they also pose challenges. Daniel Reitberg addresses concerns about workforce displacement and the need for upskilling to work alongside AI-powered systems. Adapting to this technological shift requires a proactive approach from both industries and employees.

AI Ethics and Security: Safeguarding the Future

As AI and robotics converge in manufacturing, ethical considerations and security become paramount. Daniel Reitberg discusses the importance of responsible AI use, data security, and the need for regulations to ensure the ethical and safe deployment of AI-enabled robotics.

The Future Unfolds: AI-Enabled Manufacturing in Action

In conclusion, Daniel Reitberg’s exploration of AI-enabled robotics reveals a future where machines are not just tools but intelligent partners in manufacturing. This evolution promises greater efficiency, higher quality products, and opportunities for human workers to focus on more meaningful tasks. As industries embrace this transformative technology, the landscape of manufacturing will undergo a profound and exciting change.